We're Here For You

capabilities

innovators in textile manufacturing

At Milliken, we take pride in our rich legacy of innovation, sustainability, and excellence in textile manufacturing. Our capabilities are designed to meet industry standards and redefine them. Explore our manufacturing prowess, materials, and commitment to collaboration as we usher in the future of textiles.

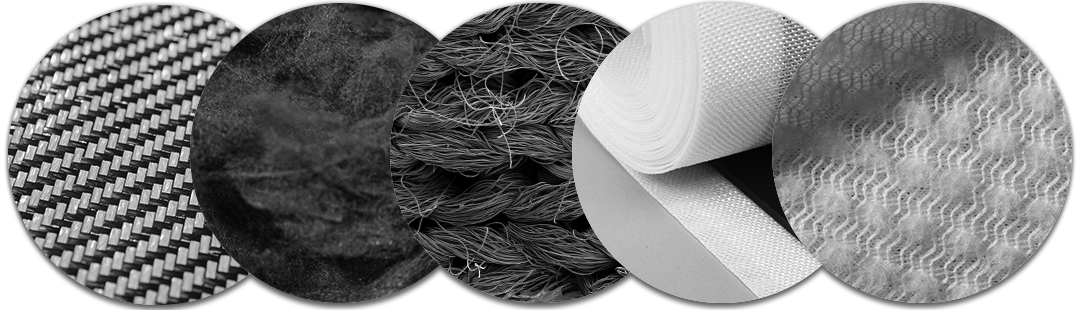

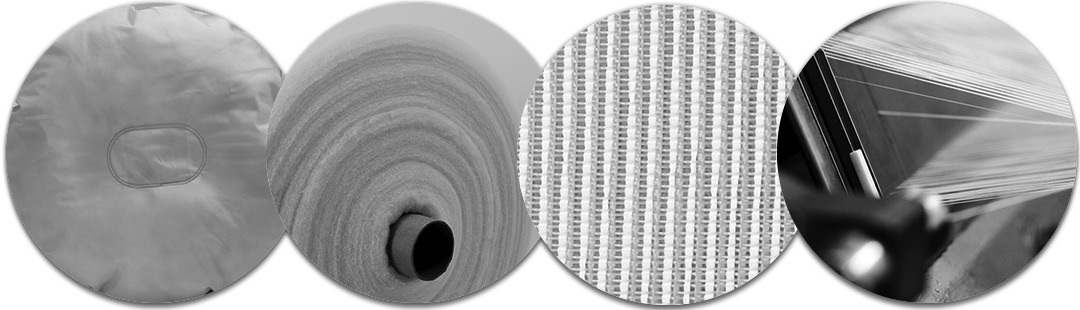

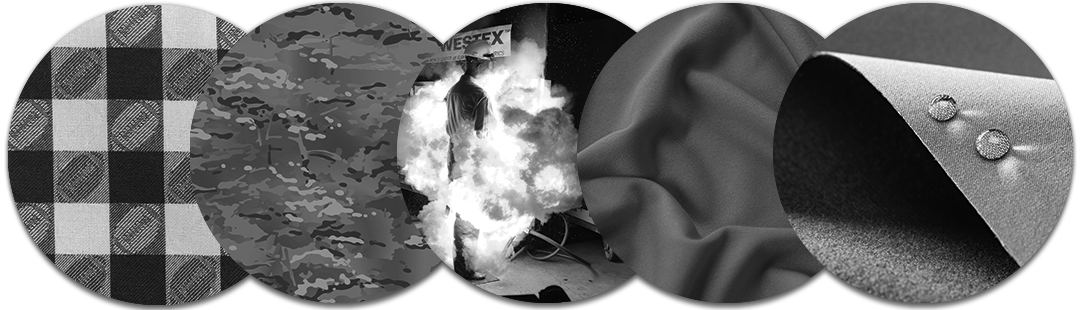

Our Manufacturing Capabilities

As a vertical textile manufacturer, we offer a wide range of yarn technologies, fabric and composite formation techniques, and dyeing and fabric finishing capabilities to meet the diverse performance demands the textile industry requires.

Supporting Stories

Solving Algae Problems

Milliken Textiles and Gross-Wen Technology development teams partnered to excel commercialization.

High-Performing Warmth

We can help protect against extreme cold-weather conditions by layering the right fabrics for your needs.

Prioritizing Production Efficiency

MilliCap was developed to shorten tire manufacturing cycles, improve cost efficiencies while prioritizing sustainability, and reduce the rubber weight.

Reinventing The Standard

We’ve been working on next-generation soil release technologies for years, and as of 2023, are pleased to offer a new, non-pfas soil release technology.

RAPID PROTOTYPE CENTER:

FROM FIBER TO FINISHED FABRIC

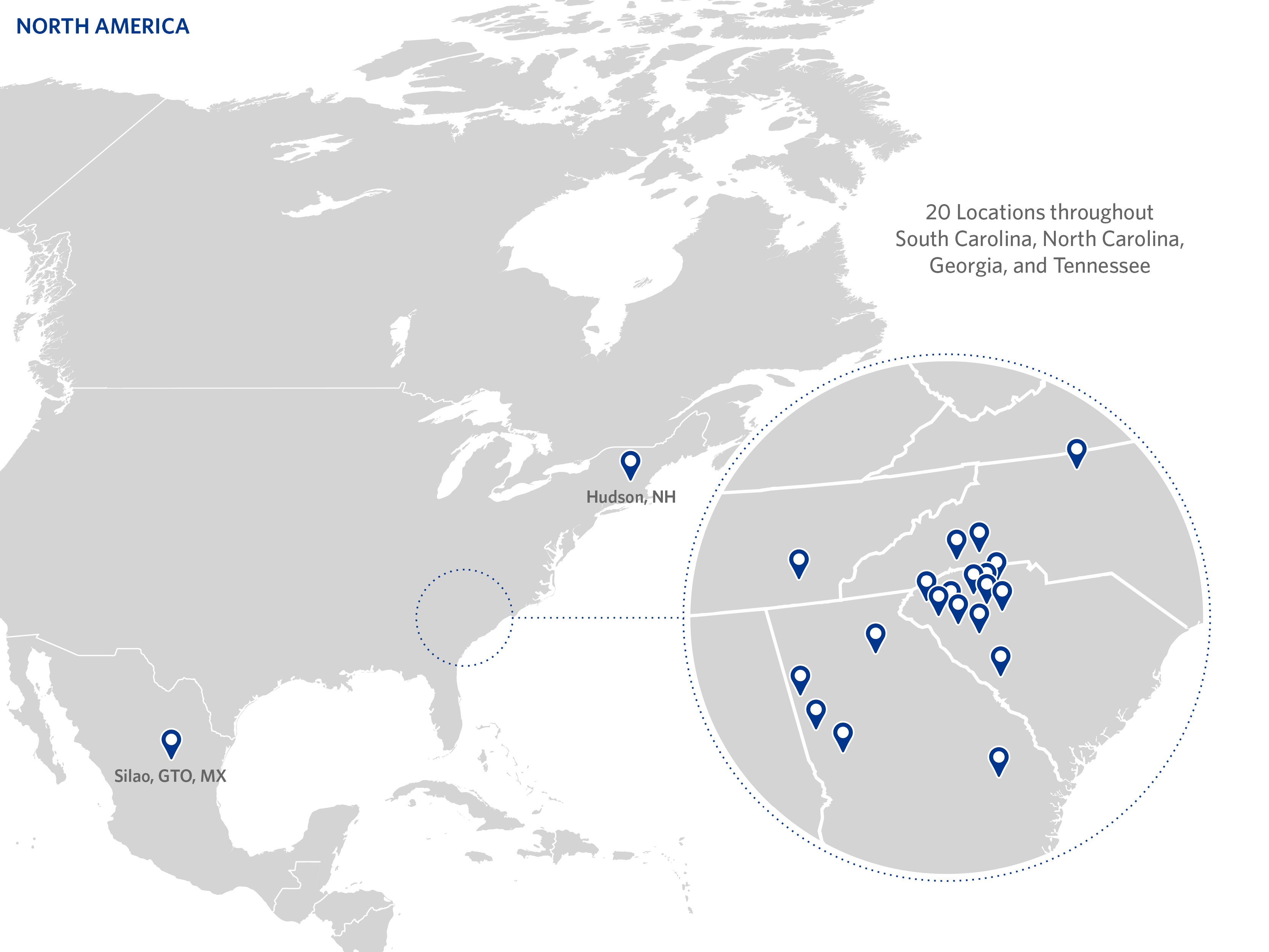

Our Spartanburg, SC headquarters houses one of the largest private textile research facilities in the world and a state-of-the-art rapid prototyping center. With both standard testing equipment, as well as equipment designed specifically for our diverse product needs, our experts can turn projects in 1.5 weeks instead of the industry standard 8 weeks, creating shorter lead times and lower development costs.

NEED MORE INFOView Our Textile Locations

Anything. Everywhere.

Right now, all over the world, Milliken & Company textile innovations help people feel safer, more comfortable, more efficient, and more confident.